Quartz Watch Movements

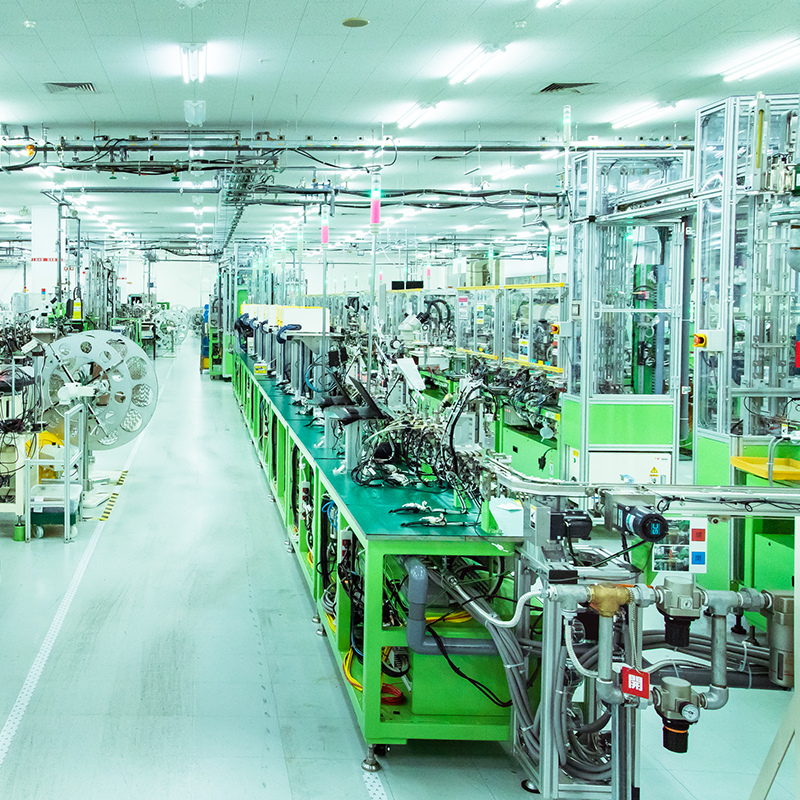

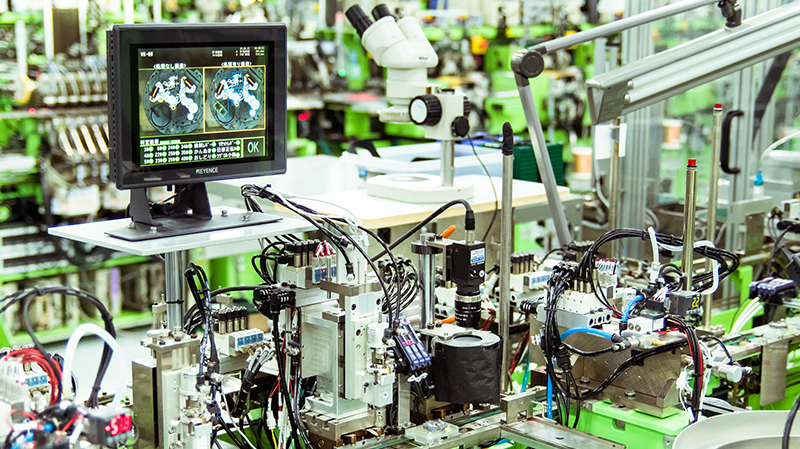

Automated assembly lines in the clean room

Automated assembly lines in the clean room

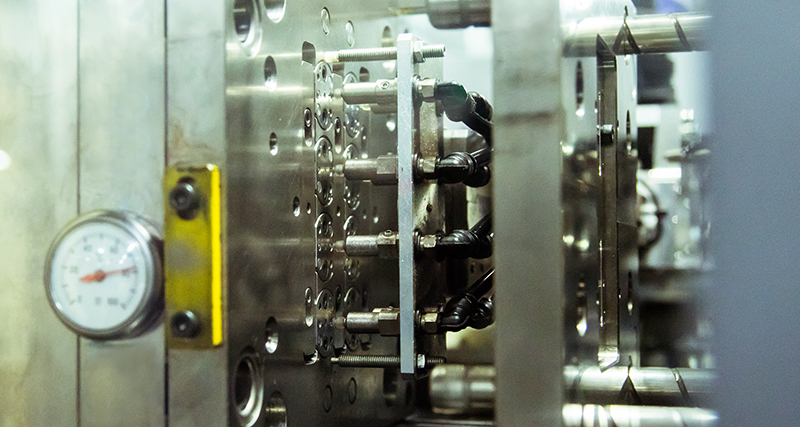

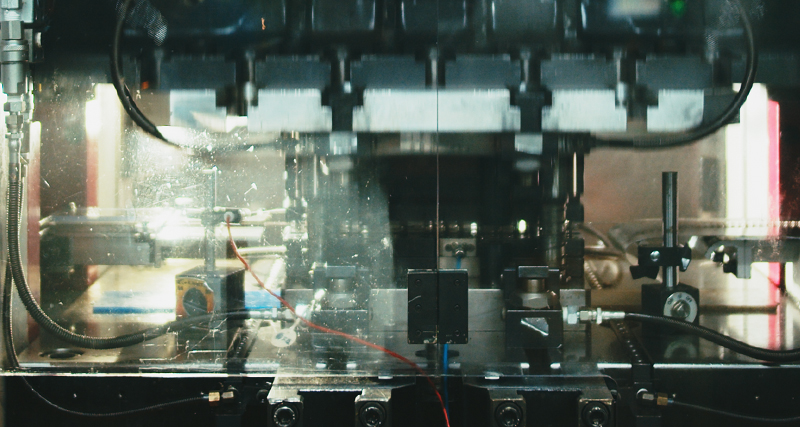

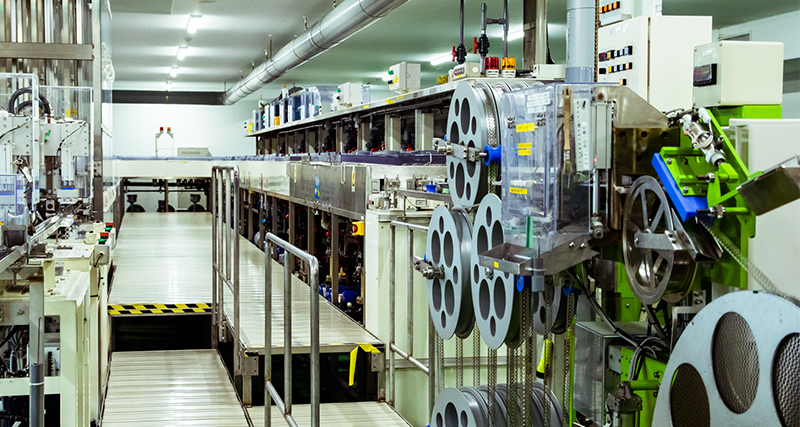

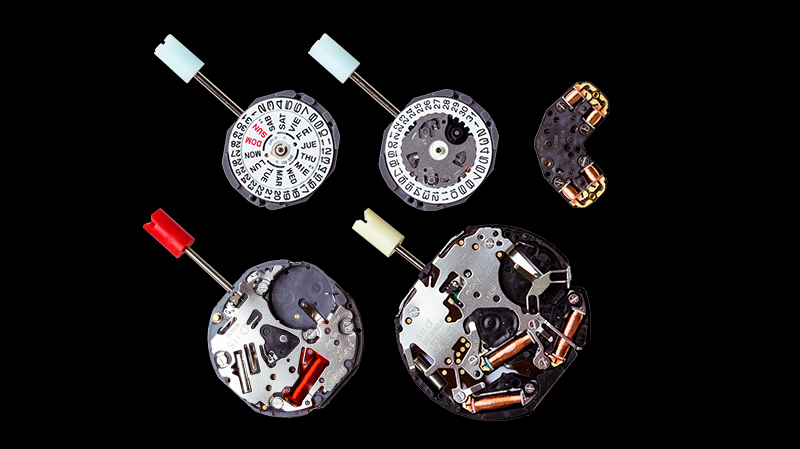

In the manufacturing process of analog quartz watch movements, we make full use of equipment such as high-speed pressing machines that can process large quantities at once and injection molding machines that can freely process both metals and plastics. These are dedicated devices that are adjusted independently and can mass-produce parts with high efficiency and high precision. This allows us to manufacture even very small, complex parts in-house. In the assembly process within the clean room, watch movements are assembled by robots with advanced programs that carry out the various operations, including assembly of each part (mounting of ICs, coil blocks, quartz crystals, etc.), accuracy adjustment, and inspection (vision system). The combination of manufacturing know-how, cultivated since the company’s founding, with the latest technology such as robots enables us to achieve both precision and productivity.

Injection molding machine for plastic parts

Injection molding machine for plastic parts

Plastic parts

Plastic parts

Pressing of precision metal parts

Pressing of precision metal parts

Metal parts

Metal parts

Hoop plating equipment

Hoop plating equipment

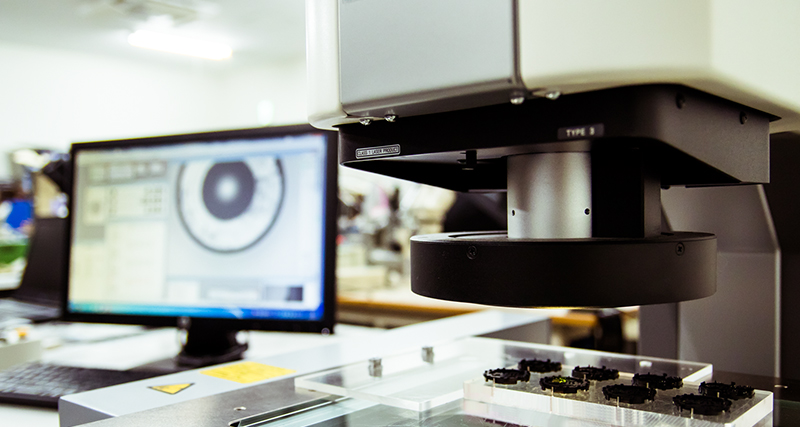

Three-dimensional measurement

Three-dimensional measurement

Pressing machine that can process large quantities

Pressing machine that can process large quantities

Movements

Movements

Coil winding

Coil winding

Quartz crystal mounting

Quartz crystal mounting

Inspection with the Vision System

Inspection with the Vision System

Completed movements

Completed movements